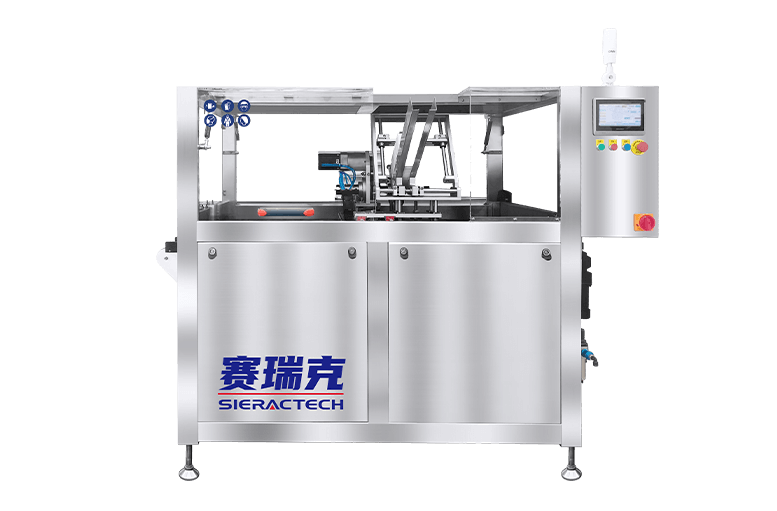

- • Filling Machine

- • Capping Machine

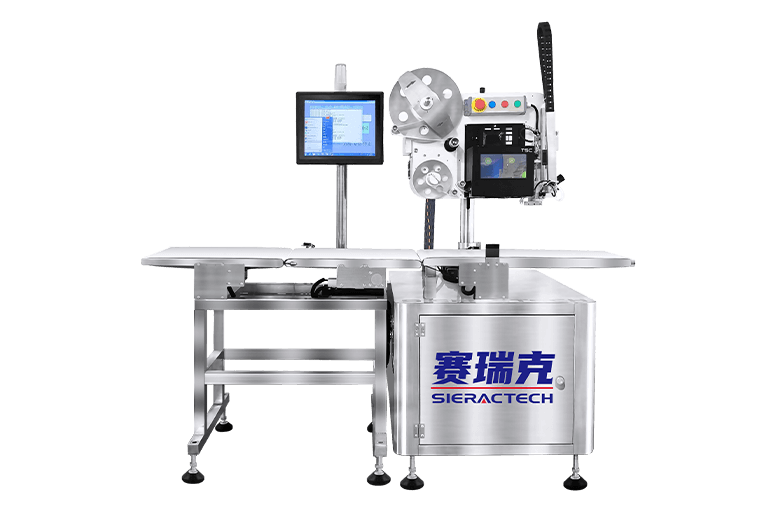

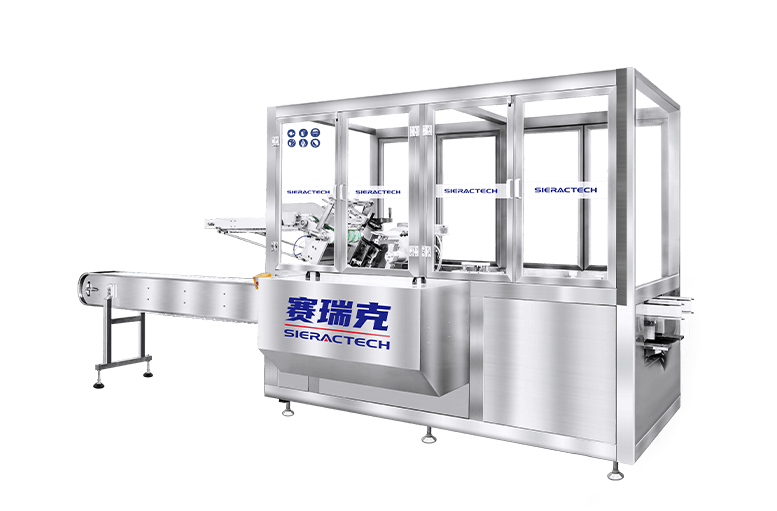

- • Labelling Machine

- • Box Packing Machine

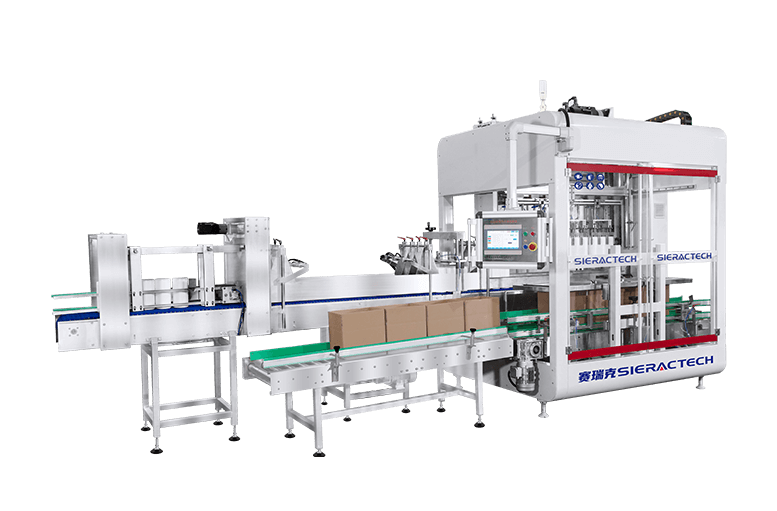

- • Case Packing Machine

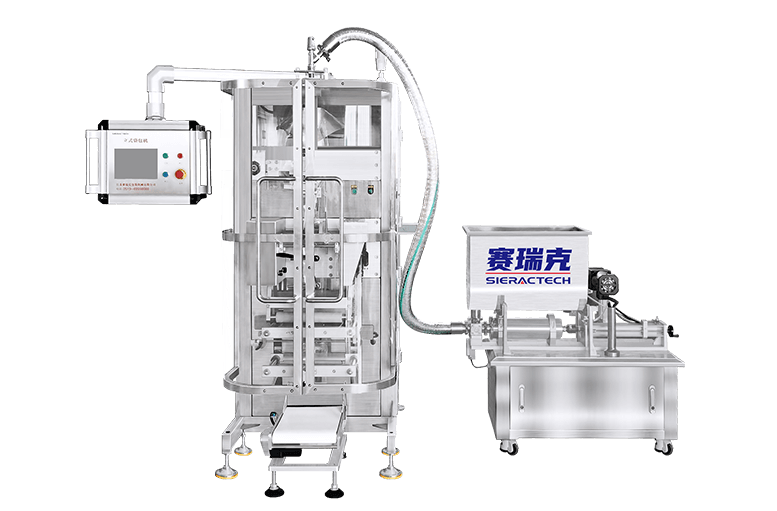

- • Bagging Machine

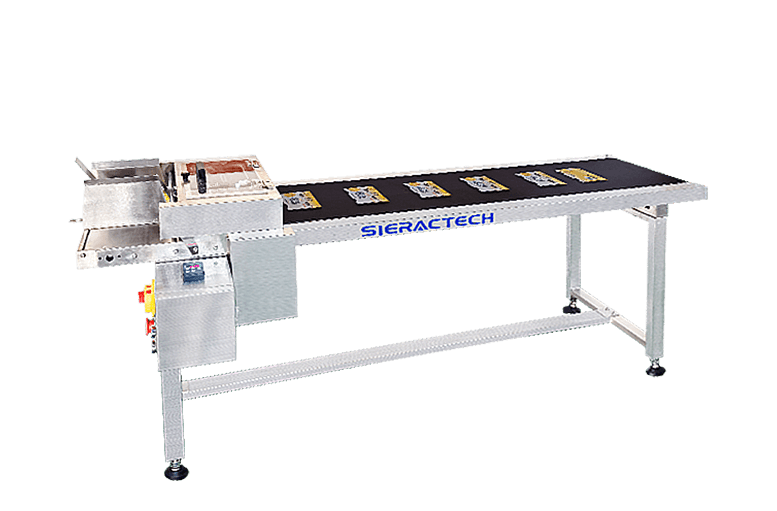

- • Set Card Machine

- • Paging Machine

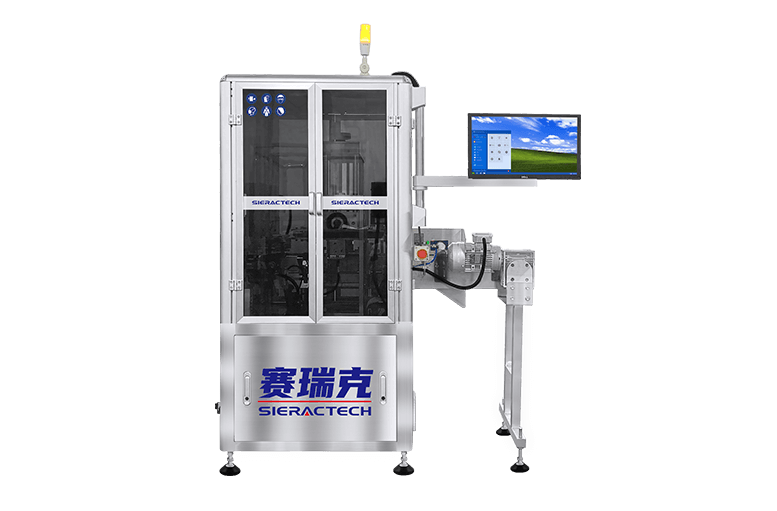

- • Bottle QR Code Scanning

- • Bag QR Code Scanning

- • Sealing Inspection

- 电话:0519-69998088

- 地址:256 Mingxin Middle Road, Wujin District, Changzhou City, Jiangsu Province

Adjustable speed

Efficient production

Multiple sizes

Quick to adjust

Vacuum suction

No drips or leaks

Material tank

Automatic supply

Material box claer

No dead corner

设备细节

Application

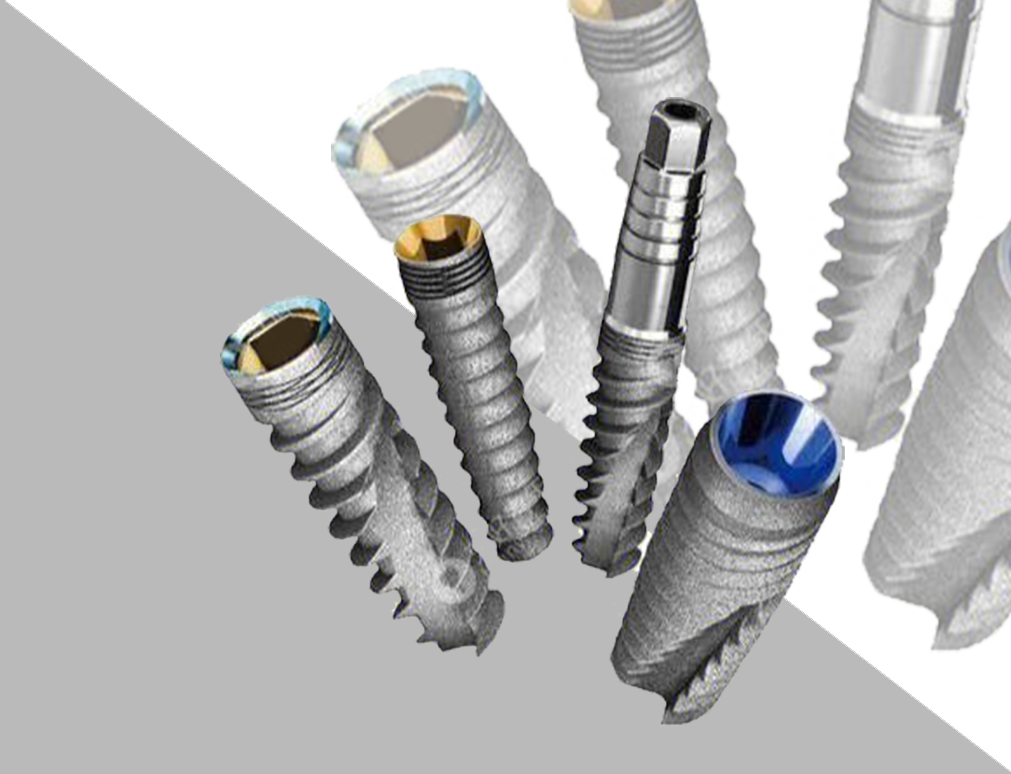

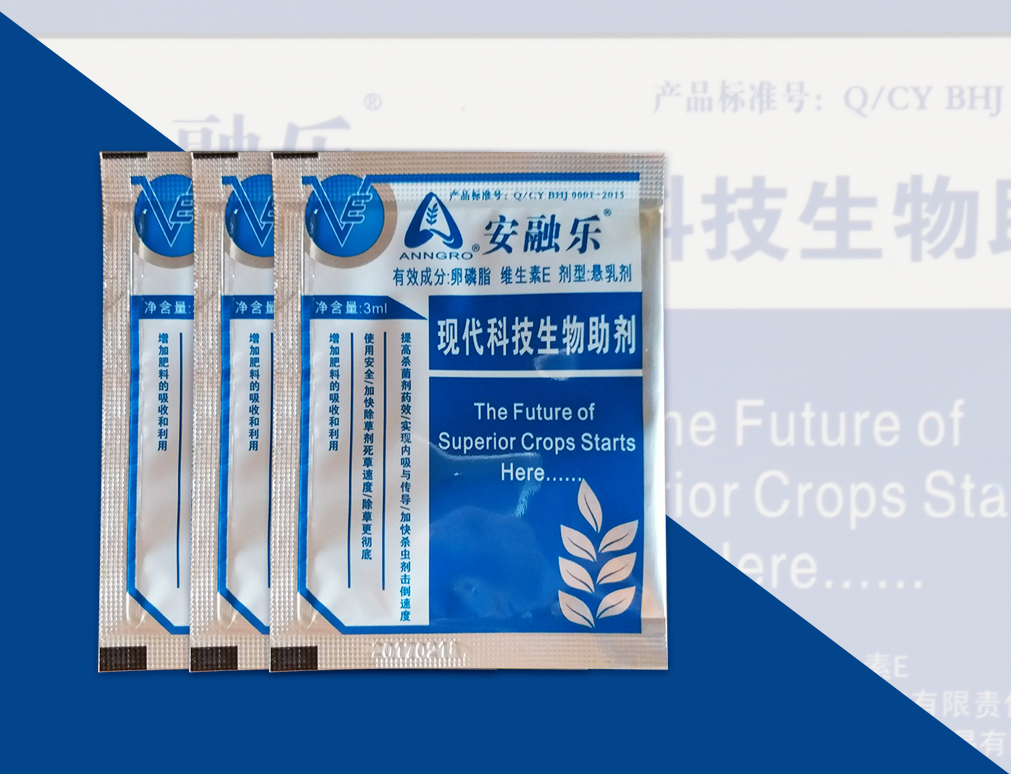

Application:Agrochemical,daily chemical,medical industry,and food industry.

Agrochemical filling

Daily chemical filling

Food filling

Daily chemical filling

Agrichemical filling

Daily chemical filling

Food filling

Daily chemical filling

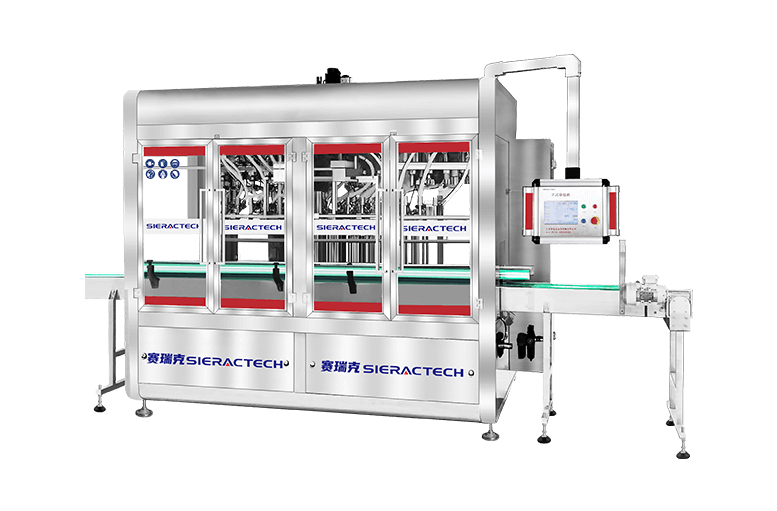

Equipment parameter

| Model: | GZF-H12 Upper Weighing Intelligent Filling Machine | Material: | 304/316 combine stainless steel and carbon steel |

| Type of filling: | Upper weighing filling | Arrangement structure: | In-line type |

| Number of filling head: | 12 heads | Filling head: | Internally blocked filling nozzle (6L) |

| Filling capacity specifications: | 500L | Filling error: | 土0.4%(according to material) |

| Application range: | 1kg 5kg | Speed of packing: | 2.5kg size>50 bottles/min |

| Power: | 5KW | Gas comsumption: | 80L/min |

| Power supply: | 380V/50HZ | Weight: | 2000KG |

Video

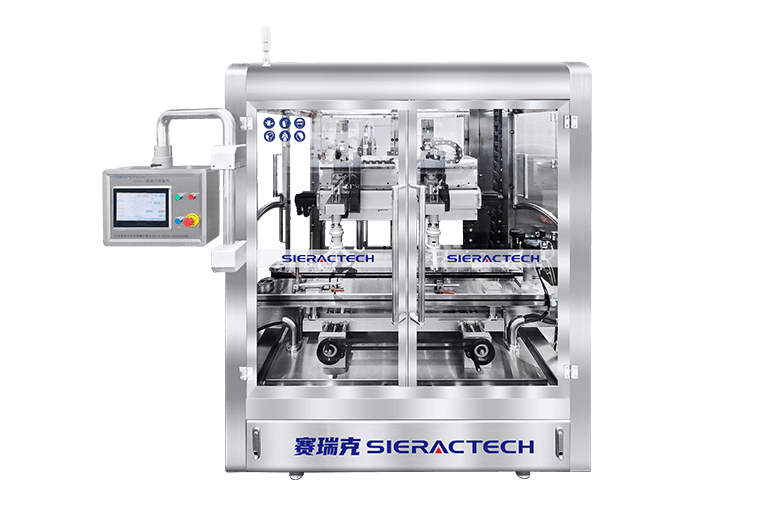

Advantages

1

Weighing filling

It can fill at multiple speeds and fill accurately.Bucket barrel and steelyard are separated.

2

Hopper pressurization

It can fill at high speed and suitable for various viscosity materials.

3

Vertical filling cylinder

The thickness of the cylinder can be freely controlled and there is no splashing during the filling process. The material box has no dead corners and is cleaned 360 degrees without dead corners.

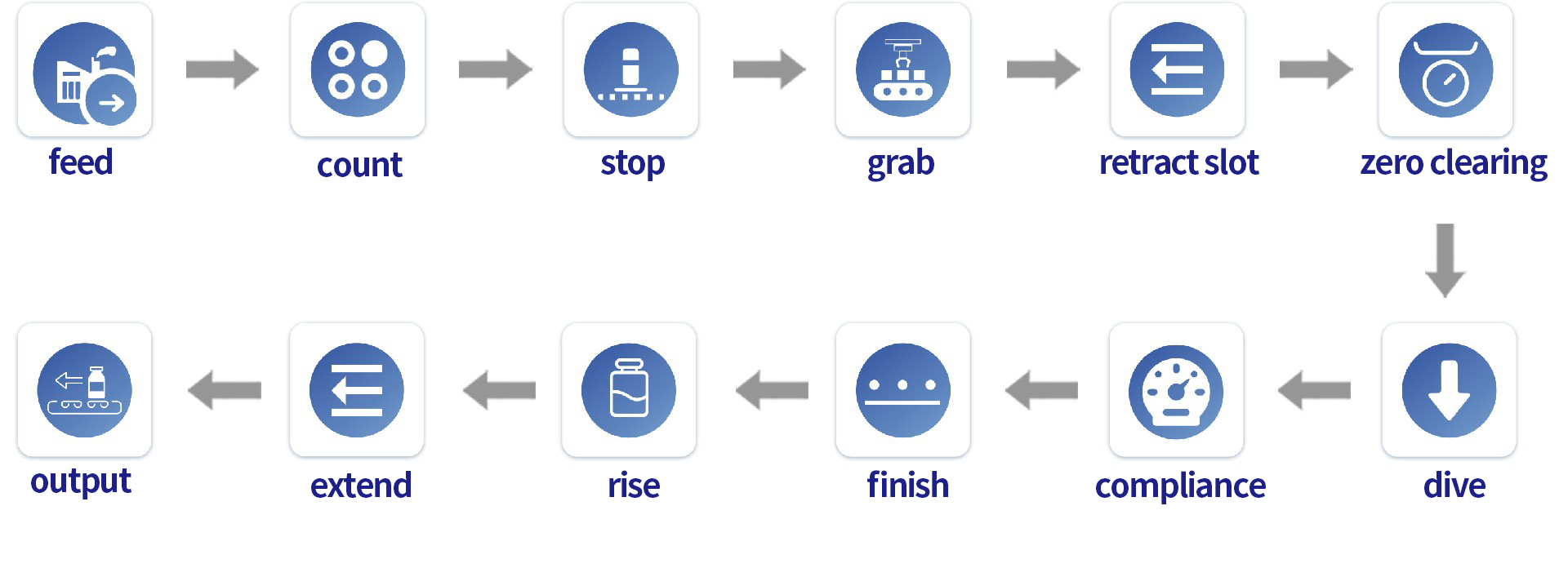

Process