- • Filling Machine

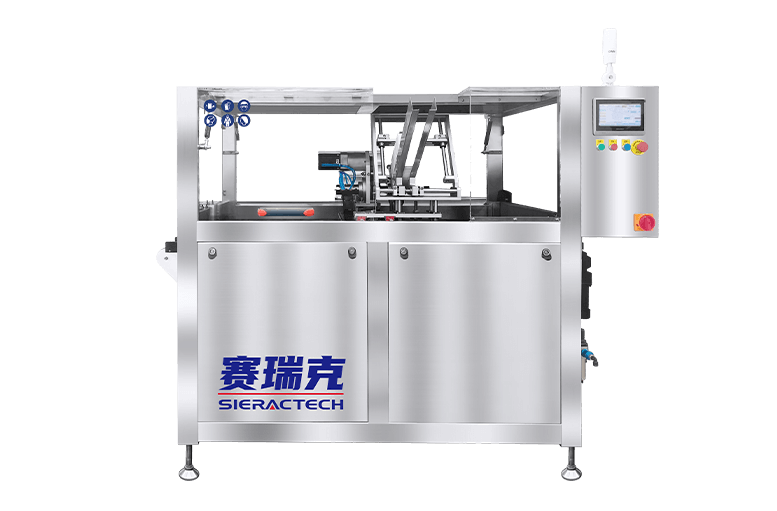

- • Capping Machine

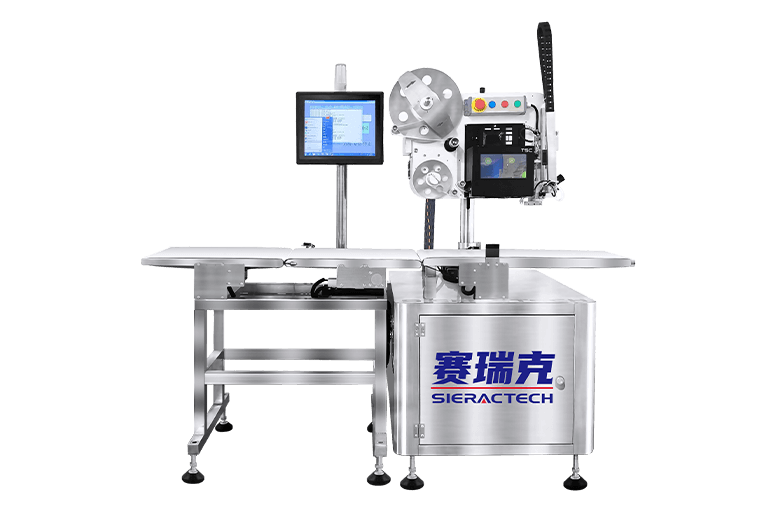

- • Labelling Machine

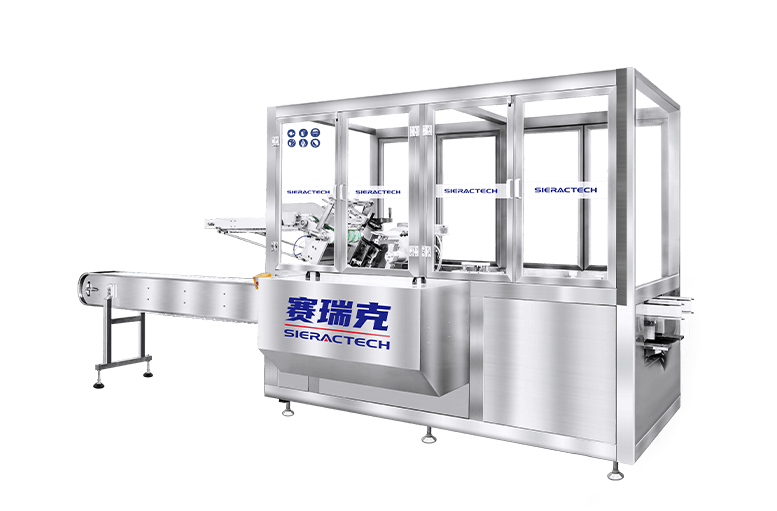

- • Box Packing Machine

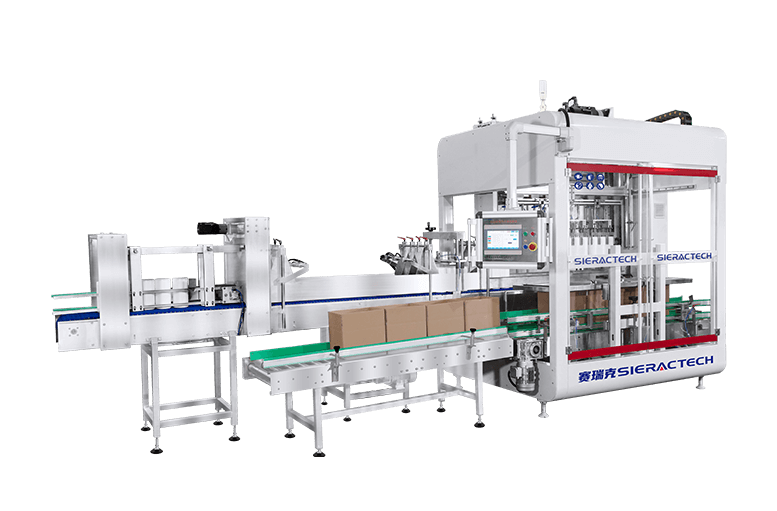

- • Case Packing Machine

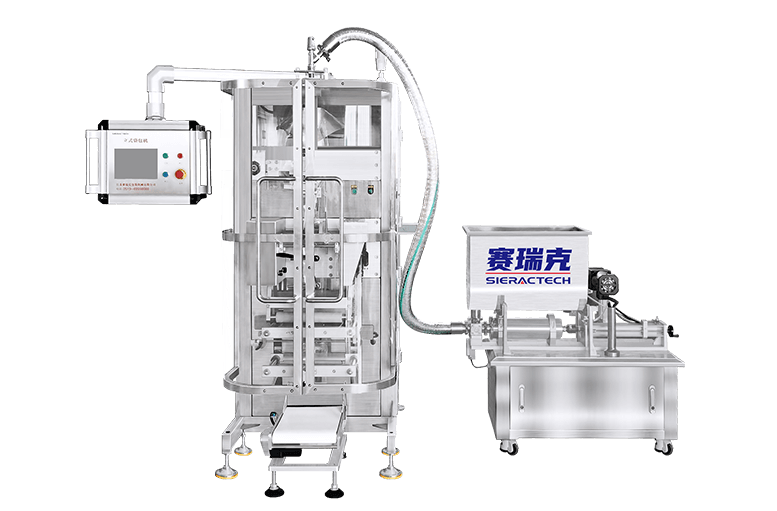

- • Bagging Machine

- • Set Card Machine

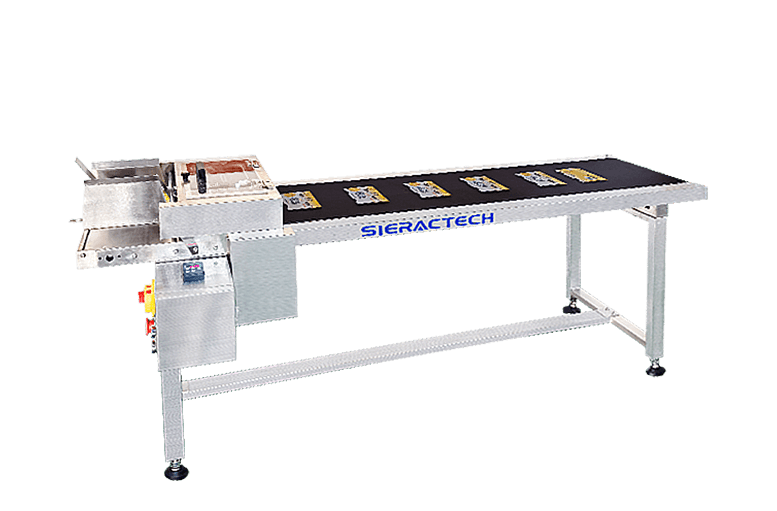

- • Paging Machine

- • Bottle QR Code Scanning

- • Bag QR Code Scanning

- • Sealing Inspection

- Tel: 0519-69998088

- Add.: 256 Mingxin Middle Road, Wujin District, Changzhou City, Jiangsu Province

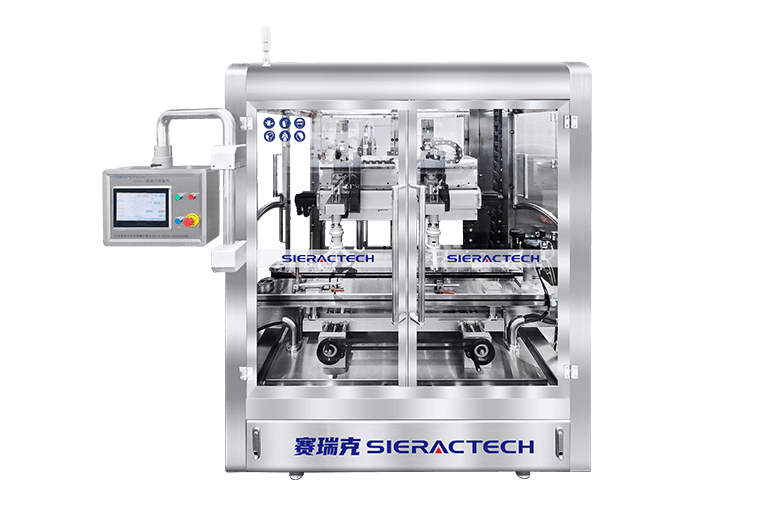

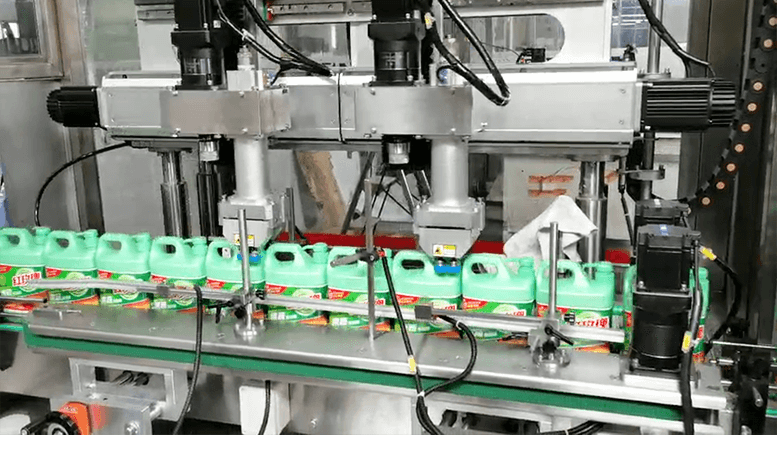

Rotate and rub cap

Multiple purposes

Follow rotating cap

No pour or splash

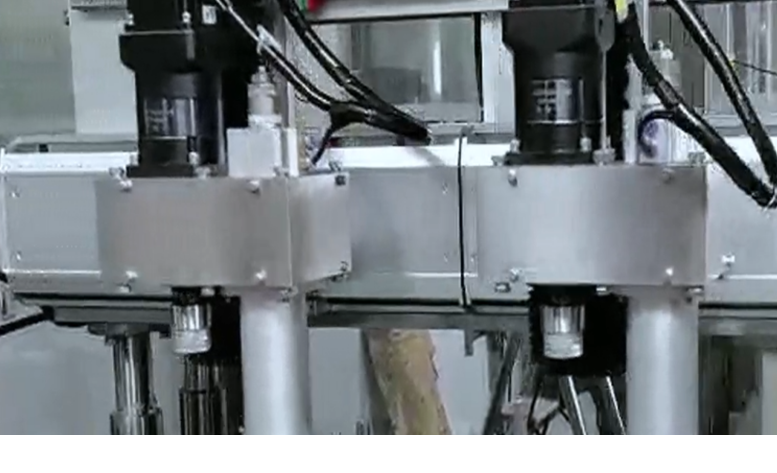

Servo motor

Stable and reliable

Up and down

Easy adjustment

Intelligent monitor

Stable operation

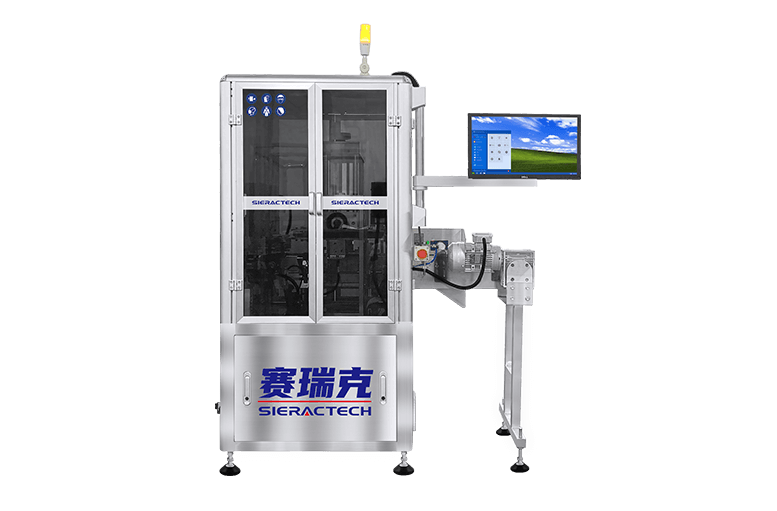

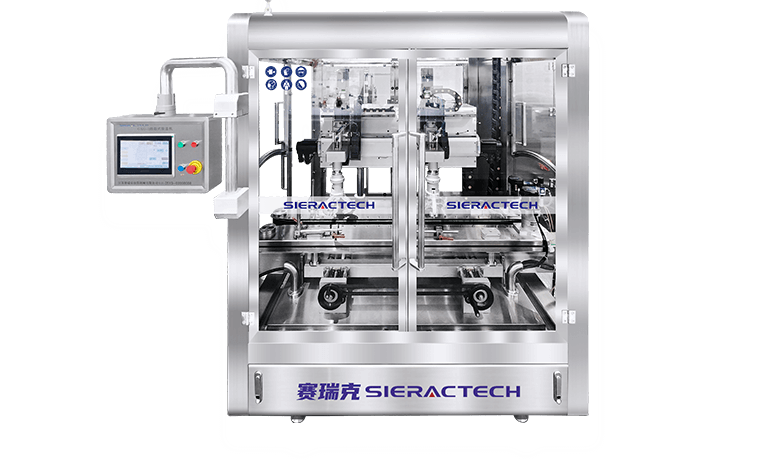

Details of machine

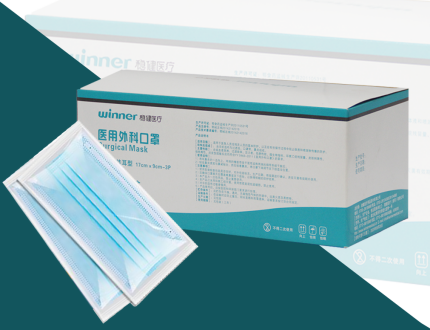

Application

Application:Agrochemical,daily chemical,medical industry,and food industry.

Daily chemical cap

Daily chemical cap

Daily chemical spray cap

Daily chemical duckbill cap

Daily chemical round cap

Daily chemical cap

Daily chemical spray cap

Daily chemical duckbill cap

Equipment parameter

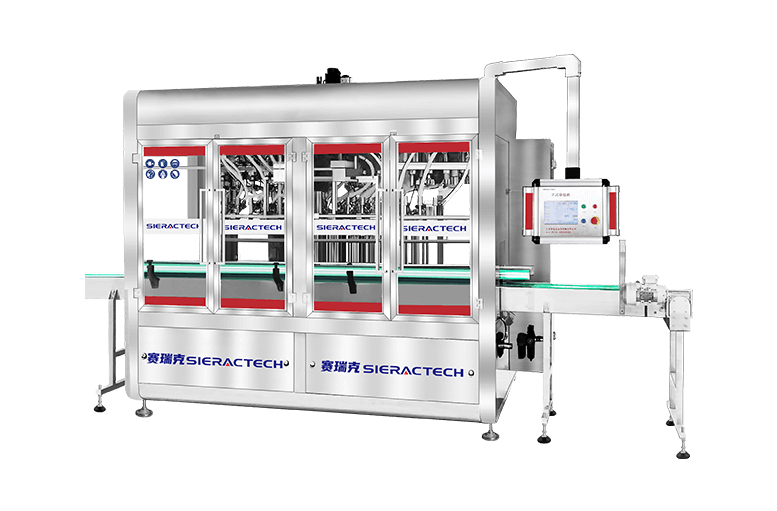

| Model: | XGC-H2 Tracing Intelligent Capping Machine | Speed of packing: | 4000 bottles/h |

| Material: | 304 stainless steel | Power: | ≤4KW |

| Driving method: | Servo transmission | Gas comsumption: | 15L/min |

| Type of capping: | Inline tracking rotary cap | Number of capping heads: | 2 heads |

| Qualification rate of rotating cap: | ≥99% | Power supply: | 380V/50HZ |

| Application range: | Daily chemical, agrichemical, medical industry, food industry | Size: | 2500x1700x2400mm(lengthxwidthxheight) |

| Screw cap torque: | Servo adjustable | Weight: | 800KG |

Video

Advantages

1

Quick adjustment

The cap rubbing and rotating mechanisms adopt a quick installation design, and the entire machine servo is adjusted with one click.

2

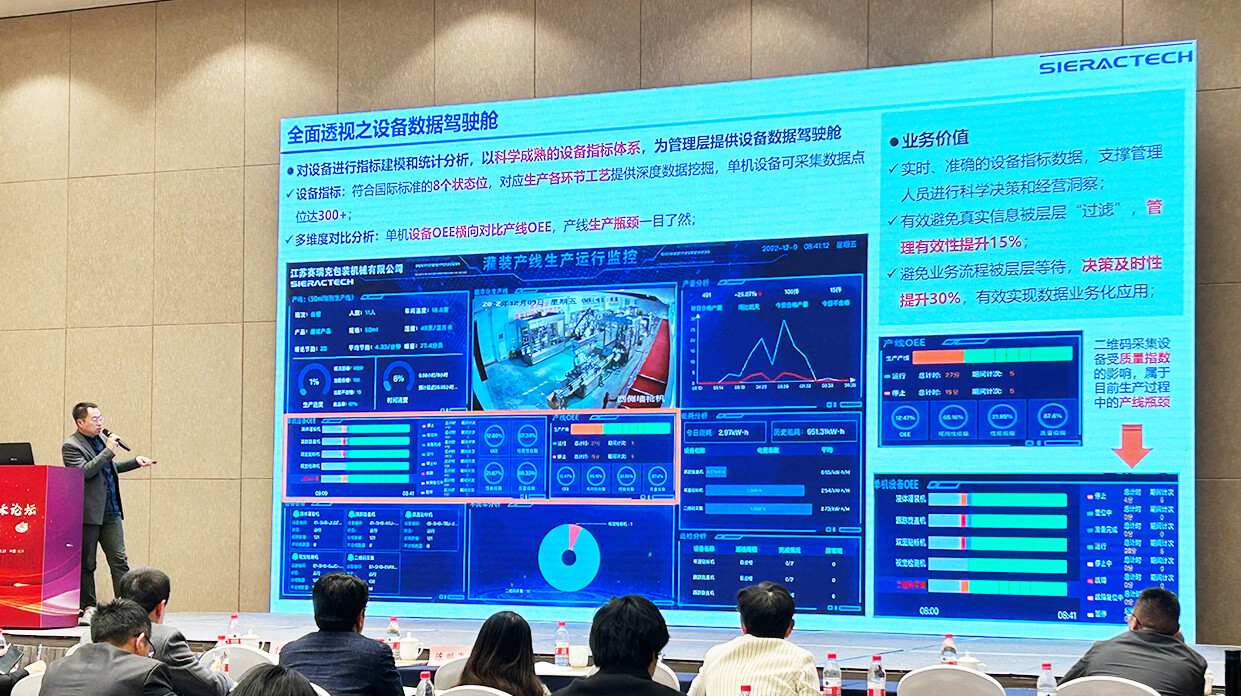

Production monitoring

It is equipped with intelligent production monitoring functions such as bottle inversion detection, bottle blockage detection, and monitoring of bottle cap not tightened.

3

Stable production

It can intelligently reject defective products, track the constant torque output of the rotating cap, and ensure that the bottle does not stop or splash.

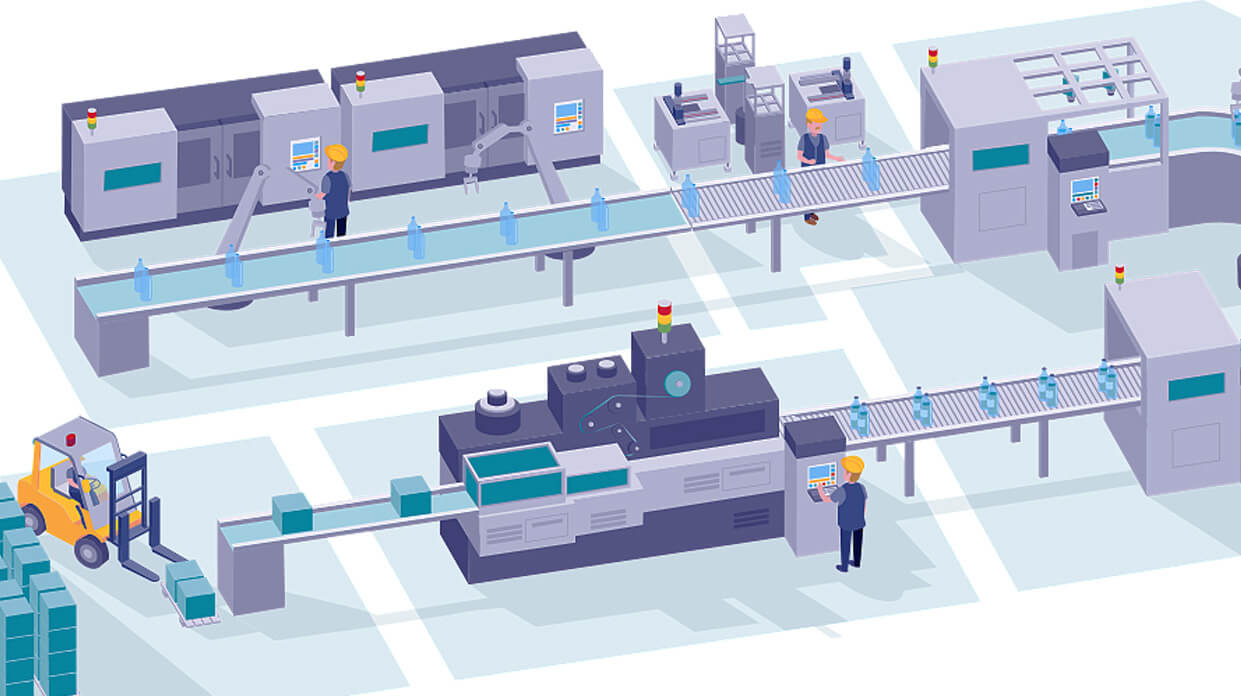

Process